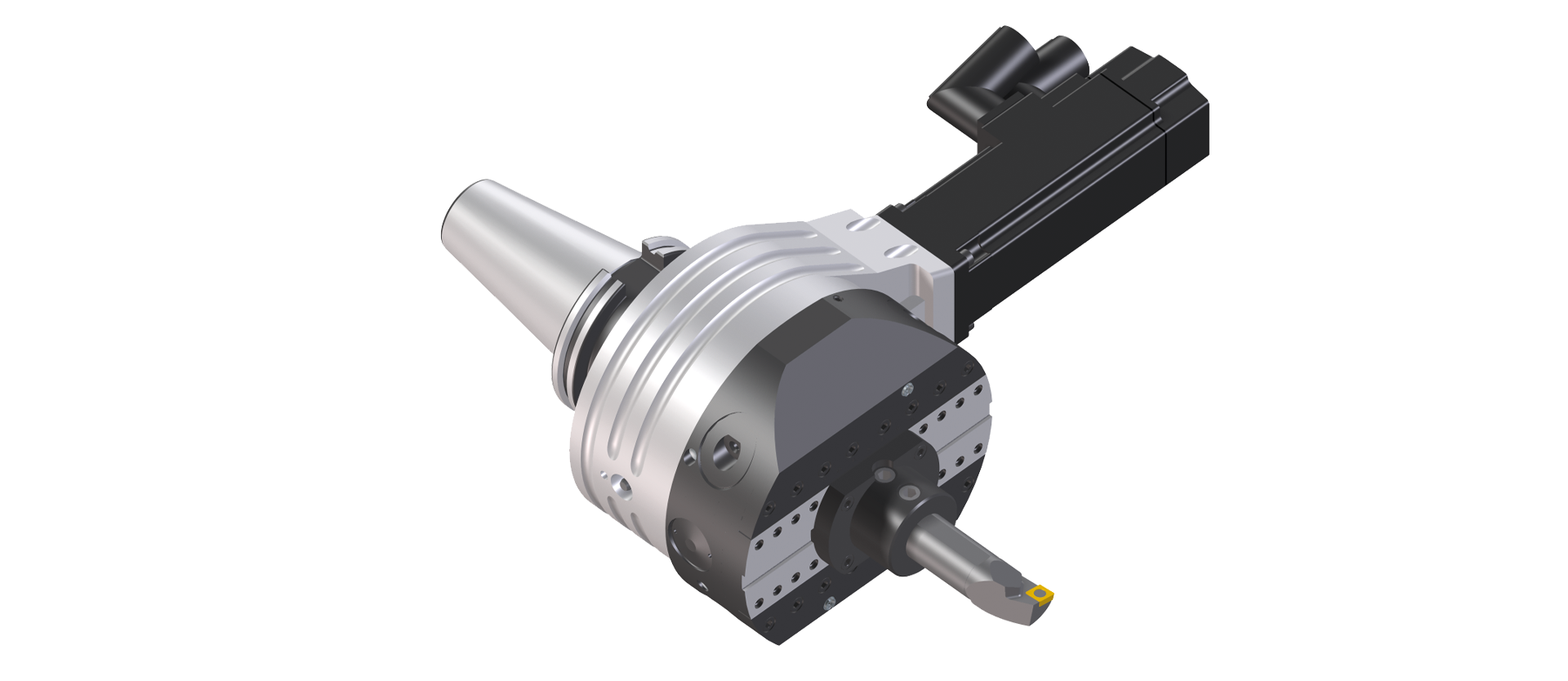

TA-TRONIC

U-Axis heads, manually applicable

NC heads with integrated motor for complex machining, manually applicable on boring machines, machining centers, and special-purpose machines, controlled via U-axis.

| Ref | Uniqe code |

|---|---|

| KIT K02 TA-T2.110 SIEMENS | 501201100400 |

| KIT K02 TA-T2.110 FANUC | 501201100800 |

| KIT K02 TA-T2.170 SIEMENS | 501201700400 |

| KIT K02 TA-T2.170 FANUC | 501201700800 |

| DIN69871-AD40 – HT5.36.5 | 41HT05024000 |

| DIN69871-AD40 – HT5.44.5 | 41HT05024001 |

| DIN69871-AD50 – HT5.36.5 | 41HT05025000 |

| DIN69871-AD50 – HT8.36.5 | 41HT08025000 |

| MAS403BT-AD40 – HT5.27 | 41HT05034000 |

| MAS403BT-AD40 – HT5.36.5 | 41HT05034001 |

| MAS403BT-AD40 – HT5.44.5 | 41HT05034002 |

| MAS403BT-AD50 – HT5.54.5 | 41HT05035000 |

| MAS403BT-AD50 – HT8.38.5 | 41HT08035000 |

| HSK 63 – HT5.54.5 | 41HT05046300 |

| HSK 100 – HT5.60.5 | 41HT05041000 |

| HSK 100 – HT8.76.5 | 41HT08041000 |

| CAT 40 UNC – HT5.54.5 | 41HT05054000 |

| CAT 50 UNC – HT5.36.5 | 41HT05055000 |

| CAT 50 UNC – HT8.50.5 | 41HT08055000 |

| P 120 TA-C2.110 / TA-T2.110 | 431550160250 |

| P 120 TA-C2.170 / TA-T2.170 | 431550250380 |

| P 130 TA-C2.110 / TA-T2.110 | 433040250950 |

| P 130 TA-C2.170 / TA-T2.170 | 433054381520 |

TA-TRONIC are NC heads for complex machining operations, designed to be manually mounted on small boring machines, machining centers and special-purpose machines.

The integrated motor, connected to the U-axis of the machine tool’s numerical control, enables operations such as boring, inner facing, outer facing, back-facing, grooving, internal and external turning, phonographic spirals, tapered threads and borings as well as concave and convex radius machining through interpolation with other axes.

The fixed body is held in position by a flange or, for lighter operations, by a simple anti-rotation pin.

Contact us

Have questions or need assistance? Fill out the form and we'll get back to you as soon as possible.